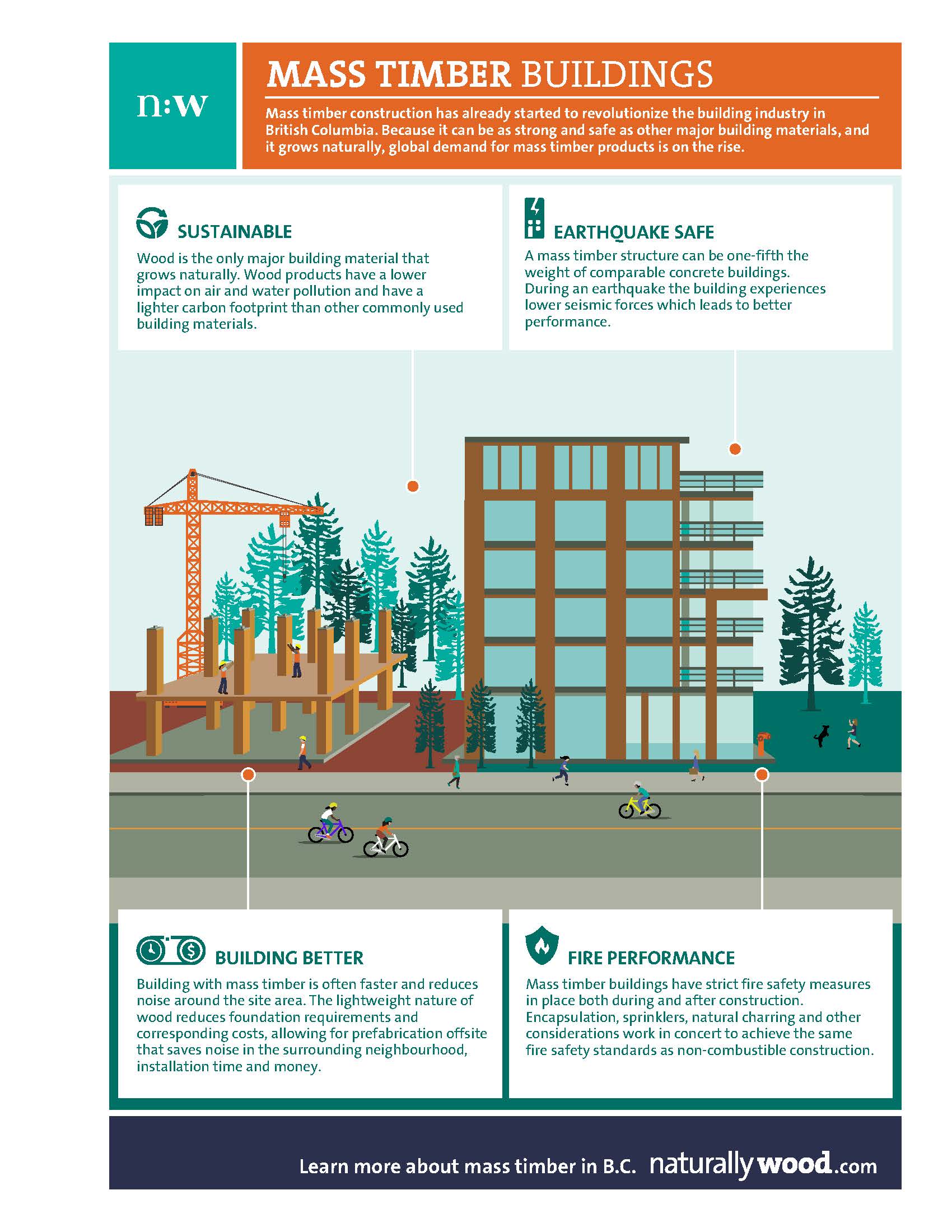

Technology meets tradition in this multipurpose aviation centre that draws inspiration from historic aircraft design and takes advantage of the latest in mass timber building systems. The KF Aerospace Centre for Excellence is a non-profit exhibition and conference centre designed to celebrate the Okanagan’s 50-year history of aviation while delivering a memorable and immersive experience. This legacy project includes interactive exhibits, holographic media, and hands-on displays that put visitors “in the cockpit”.

- Dowel-laminated timber (DLT) will be used for the roof and floors of the hub, and cross-laminated timber (CLT) panels in the hangar walls create the lateral force-resisting system.

- Along with its signature roof, the facility features what will likely be a world-first doubly-curved, self-supporting CLT staircase descending to the centre’s main lobby.

Architecting an immersive experience

The Centre is not just an exhibition space but a nerve centre for the aviation sector, helping promote the region’s aerospace expertise. It will feature an airfield viewing gallery, cafeteria area, and conference rooms and be equipped to host public tours and educational programs. The project showcases made-in BC wood products and expertise from its innovative structural design to its locally sourced and prefabricated mass timber components. Public exhibition space will include viewing access to two large hangars housing working aircraft. These will include a Convair CV-580 and Douglas DC-3, as well as a Hawker Tempest MKII.

Mass timber spreads its wings

The vision for the building’s iconic mass timber structure all started with a simple napkin sketch by KF Aerospace’s founder and aviation enthusiast Barry Lapointe. The legacy project focuses on two key ideas: “make it feel like a plane” and “use wood wherever possible”. The design does just that: configured like an aircraft, the facility’s central two-storey hub “fuselage” is flanked by two wing-shaped hangars. Inspiration for the large sweeping and curved wooden roof draws heavily from aeronautical engineering. The building’s roof is made up of a series of strut and rib trusses to be framed in glue-laminated timber (glulam).

Calculating the best option

The solution came out of an in-depth exploration of airfoil shapes and wing structures. The design team determined the optimal structure using the latest computational design and 3D modelling software, with a focus on creating the lightest, most efficient wing structure achievable.

Evolutionary algorithms, an optimization method that evolves multiple sets of structural options, were used to converge the design towards the best structural solution. The roof structure is designed to collect rainwater and a prominent ‘tail’ feature serves as eye-catching signage for the building’s easy-to-access location adjacent to Highway 97, the main connector for the region. Construction is underway and expected to be completed by March 2022, marking KF Aerospace’s 52nd year in the industry.

The building showcases the latest structural innovation and mass timber construction throughout the superstructure. From optimized wing-shaped hangar roofs to a world-first doubly-curved CLT staircase, a creative approach to structural engineering is pivotal to the design of this project.

Lucas Epp, P.Eng., StructureCraft