What is hybrid-timber construction?

A vast number of buildings today are erected using hybrid construction. Hybrid-timber construction systems combine wood with different materials (for example steel, concrete and glass) and techniques to deliver a wide range of structural solutions. While it is possible to construct a building entirely of wood, most wood buildings rely on some use of other materials. Nails, screws, bolts and plates for connections are a standard complement to wood construction. Hybrid-timber construction goes further, making other materials—such as steel and concrete—an integral part of a building’s structural assemblies. This mixing of materials in building systems means design teams can exploit the strength of each—optimizing structural and building performance. Projects might use one specific hybrid assembly while others might take advantage of multiple configurations.

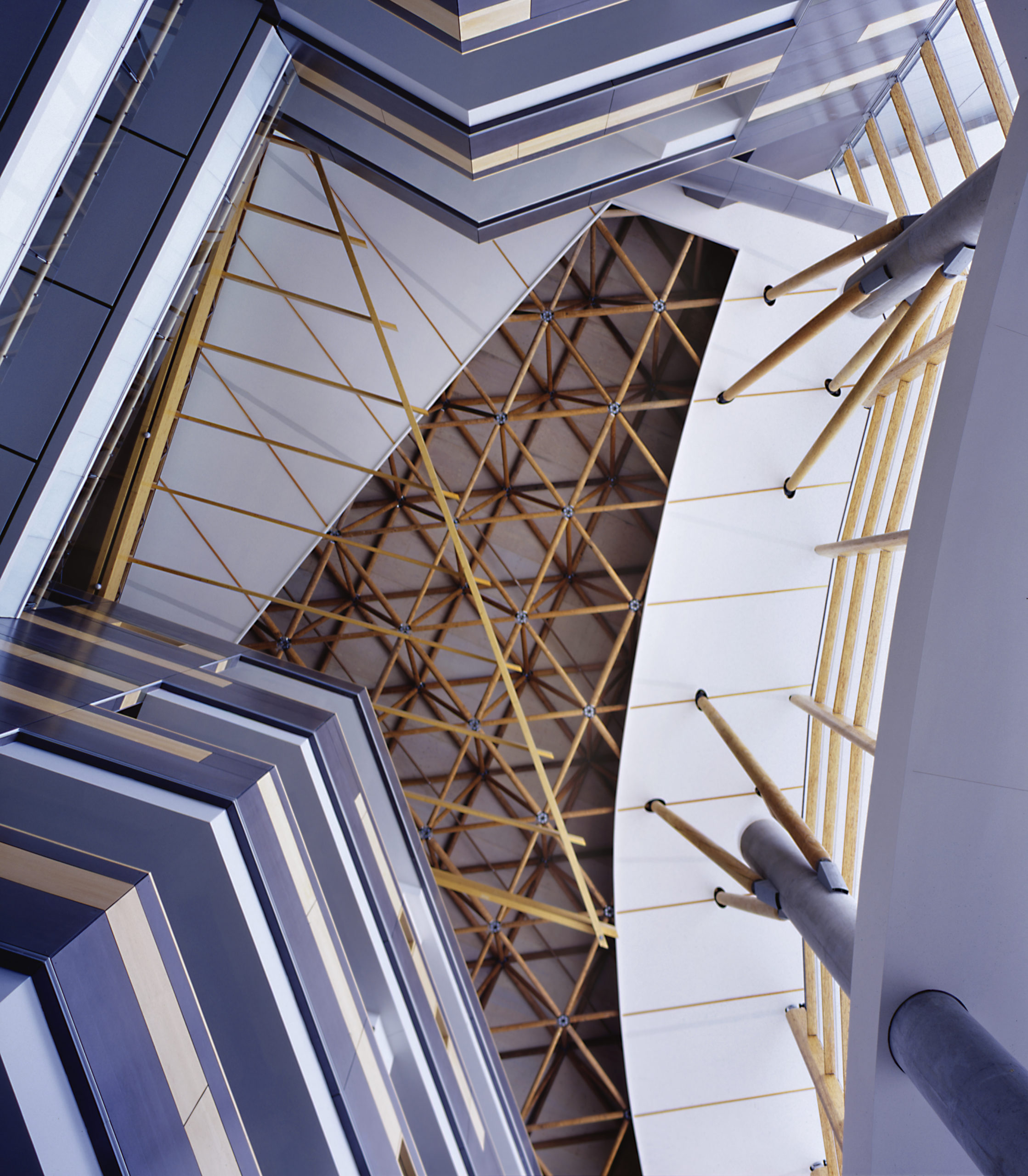

Surrey Central City | Photo credit: Nic Lehoux