Encapsulated mass timber construction char rate analysis

Conducted by GHL Consultants for Natural Resources Canada, 2020

Learn MoreFire performance, protection and safety in light-frame wood and mass timber buildings.

Sutherland School | Photo credit: Gord Wylie

Today’s modern wood-frame and mass timber buildings have a proven fire safety record. Effective design and the use of state-of-the-art fire protection technologies in timber structures provide added assurance and help save lives.

The risk of fire is a concern for all buildings and construction sites. Every building material can suffer damage from prolonged exposure to fire: steel buckles, concrete spalls and wood burns. In response, the building industry has developed technologies and evolved building codes over the last half-century to dramatically reduce the negative impacts of fire and help ensure fire-safe construction. This includes taking full advantage of fire-retardant materials, sophisticated fire detection such as optical smoke sensors, advanced sprinkler and alarm systems and other smart building technologies.

Building codes, in British Columbia, and throughout North America, ensure your safety. They’re a proven set of performance-based objectives that all buildings must comply with. Recent advancements in B.C. and around the world permit taller wood construction. Such code changes are based on rigorous research and developed by experts through a collaborative process that includes input from all segments of the building community.

King David High School | Photo credit: Martin Tessler

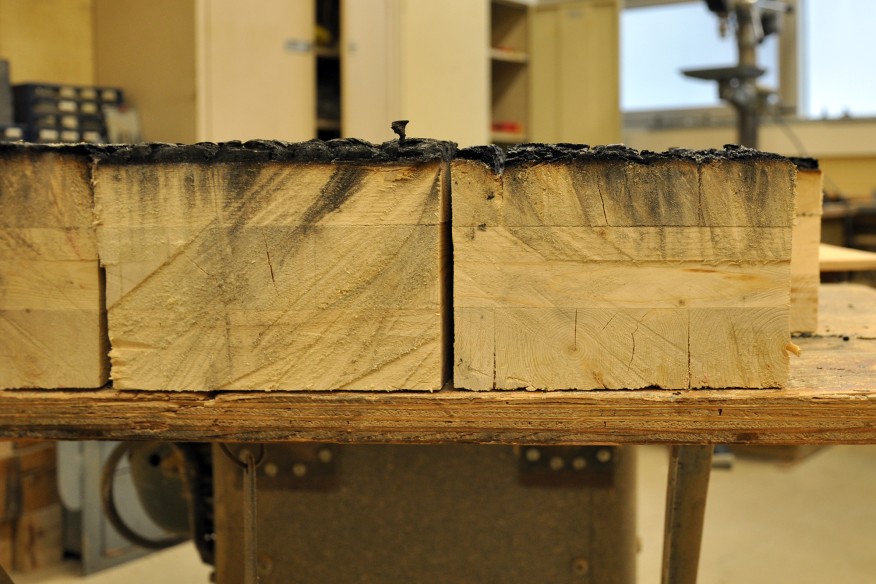

In the event of a fire, mass timber and engineered wood products char on the outside, forming a protective layer while retaining strength. This slows combustion significantly, allowing time to evacuate the building safely.

How mass timber charring protects:

Mass timber and tall wood buildings are proven to be fire safe. From cross-laminated timber (CLT) and dowel-laminated timber (DLT) to glue-laminated timber (glulam), mass timber’s strength, resilience and natural fire resistance is being backed up by some of the most comprehensive real-world testing scenarios to date.

Time and time again, testing shows in the event of a fire, mass timber and engineered wood products char on the outside, forming a protective layer while retaining strength. This slows combustion significantly, allowing time to evacuate a building safely. In fact, a recent series of national mass timber fire tests, dubbed the Mass Timber Demonstration Fire Test Program, show—even in worst-case fire scenarios—mass timber buildings provide strong fire performance similar to non-combustible construction. The bottom-line results: even under those rare conditions when fire services don’t intervene, the mass timber fire decays and begins to put itself out after ignition.

“These tests are giving municipalities, code officials, fire services and insurers a lot of good information—and it was really helpful that many of these folks were able to see the tests as they were conducted. It is becoming clearer through this research that mass timber buildings perform well and these buildings aren’t going to be any more difficult to put out a fire than a steel or a concrete building, when built to best practice standards,” says Steven Craft a fire engineering expert and founding principal at CHM Fire Consultants Ltd., one of the firms contributing to the fire test analysis and final report.

These findings add to a growing body of research and give added assurances to civic leaders, fire and rescue services, insurance underwriters and building occupants that mass timber buildings are safe. Furthermore, wood engineering and fire experts believe this latest round of fire tests provides strong evidence that the code can further evolve to allow for more exposed wood and taller mass timber buildings.

“This new series of fire testing shows that taller wood buildings, including those with exposed timber, do achieve fire safety standards and provide good fire performance, comparable to other building materials. They provide strong evidence to evolve the national building code,” explains Marc Alam, senior manager, codes and standards for Canadian Wood Council.

Mass Timber Demonstration Fire Test Program | photo credit: courtesy of Canadian Wood Council

Light-frame wood construction has a long-standing safety record in British Columbia. It is used in the vast majority of single-family homes and multi-family projects up to six storeys. While the structure may be made entirely of wood, protective materials such as gypsum wallboard can provide fire resistance as needed. Light-frame wood assemblies can resist the effects of a fire for up to two hours through design and fire-resistant materials. And research shows that light-frame wood construction is just as safe as other building types.

Light-frame construction | Photo credit: Nik West

CodeCHEK, developed under the WoodWorks BC program by the Canadian Wood Council allows users to test which type of wood construction can meet code and fire protection requirements. From light-frame wood and heavy timber to exposed and encapsulated mass timber, this tool can help troubleshoot different design options and evaluate which wood elements are permitted.

Conducted by GHL Consultants for Natural Resources Canada, 2020

Learn MoreFPInnovations March 31, 2019

Learn MoreSubscribe for the latest wood projects, developments, tools and research.