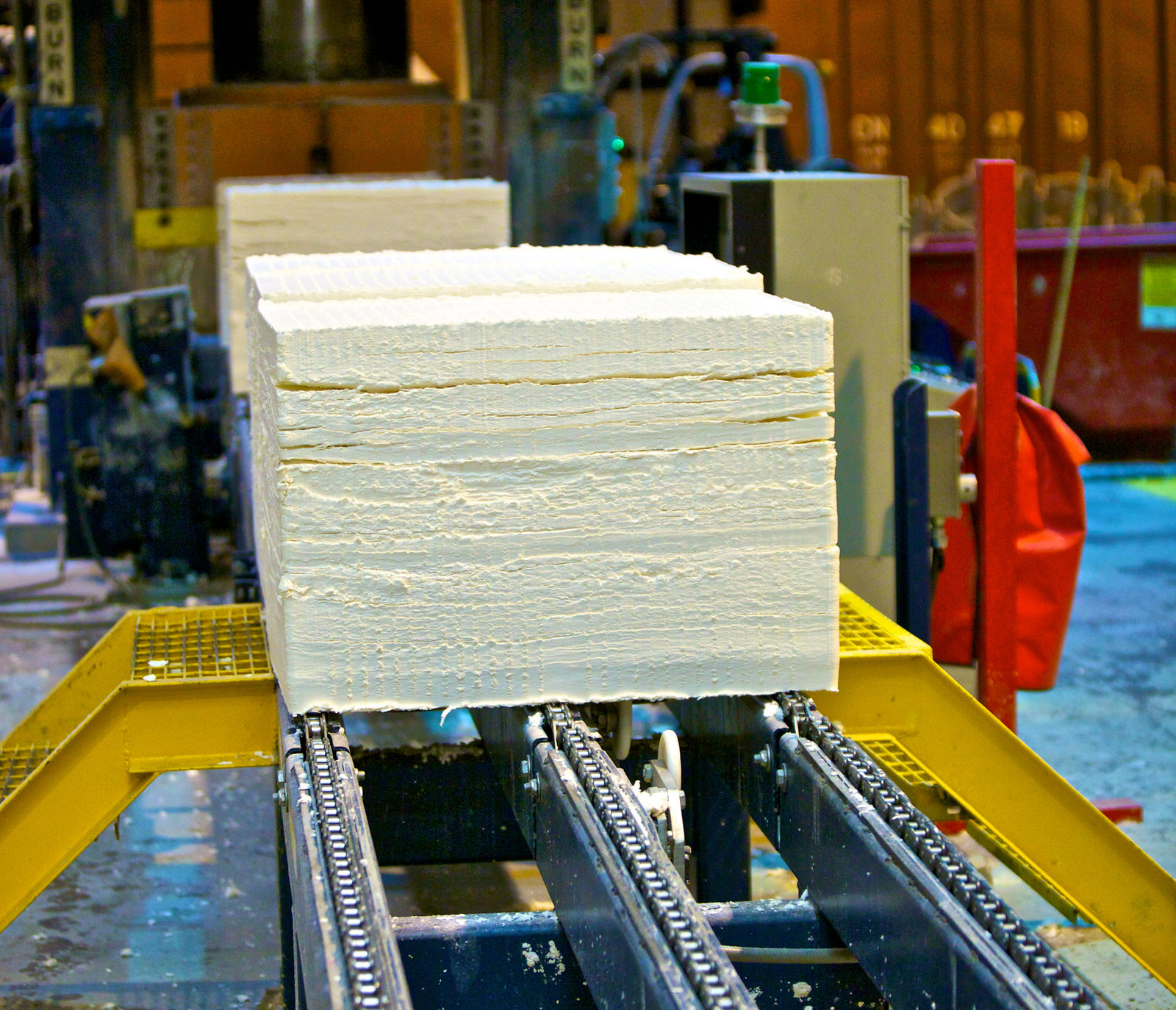

Mass timber products

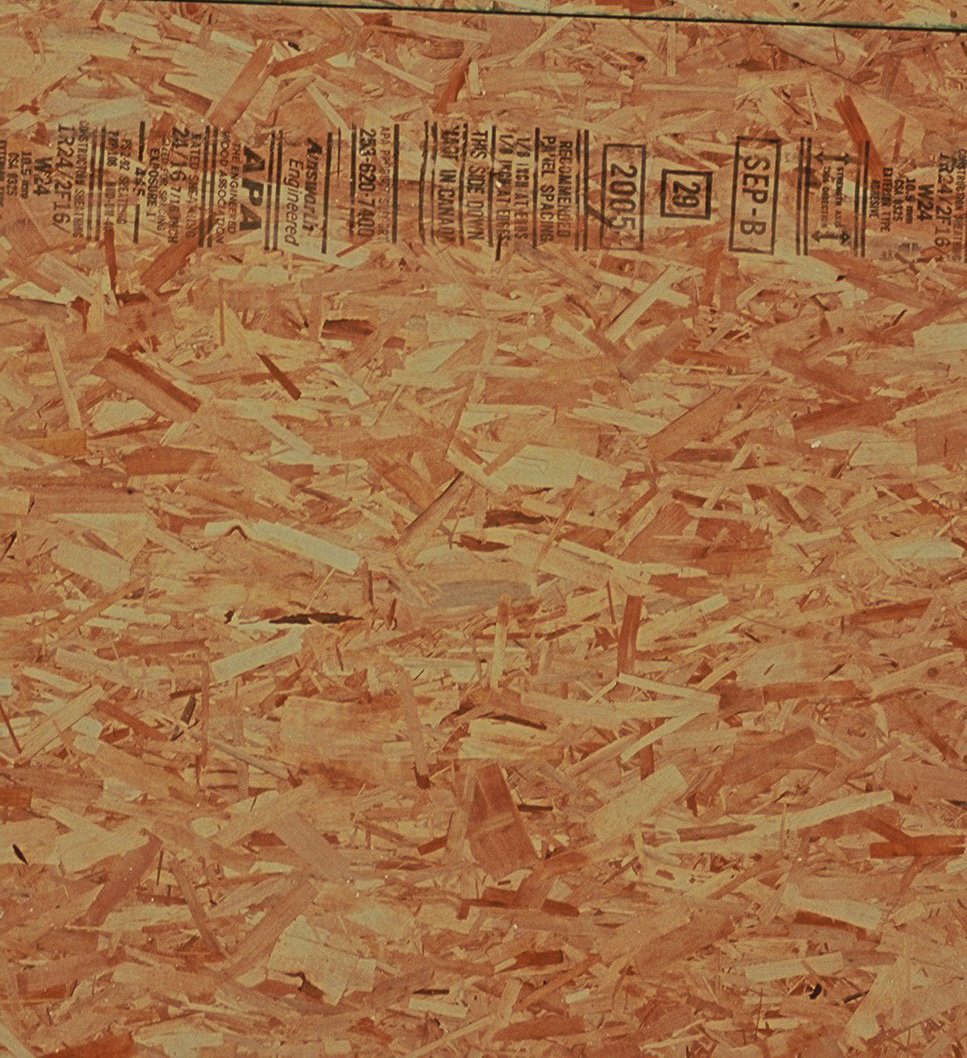

All over the world, and here in B.C, mass timber is on the rise. These advanced wood products, made by fastening, or bonding smaller wood components with adhesives, are making a whole new generation of high-performance buildings possible.