Info on pulp and paper markets

Pulp and Paper Products Council

Learn MoreThe fabrication, types, uses and applications of pulp and paper in British Columbia (B.C.).

Photo courtesy of Forest Products Association of Canada

Wood pulp is wood fibre reduced chemically or mechanically to pulp—a soft, wet, shapeless mass of material—used in the manufacture of paper and other products.

To make pulp, the cellulose fibres of wood are mechanically or chemically separated. To make chemically separated pulp, wood chips are cooked at high temperatures in a mixture of water, sodium hydroxide (NaOH), and sodium sulfide (Na2S), a process that breaks it down to a pulp. The technology entails several steps, both mechanical and chemical. Conversely, to make mechanically separated pulp, heated wood chips are grinded rather than cooked to separate the fibers. The chemical methods produce paper with higher strength and pulp that can be bleached further than the mechanical pulps. However, the mechanical process gives you a greater quantity of pulp.

Photo courtesy of Forest Products Association of Canada

B.C.’s unique climate produces tree species with naturally long, slender and thin-walled fibres. They have excellent tensile strength and produce high quality pulp suitable for a wide range of paper and fibre products. Chemical treatments produce products requiring added strength or bleaching such as shipping containers, heavy duty paper bags, speciality printing and writing papers and other fibre products requiring strength. Special grades of chemical pulps can be used to make non-paper materials, such as textiles. High-yielding mechanically treated pulp produces newsprint, specialty papers, tissue, toweling, containerboard and paperboard.

Photo courtesy of Forest Products Association of Canada

B.C. pulp is in demand worldwide for its superior ability to produce a wide range of high-quality paper products. B.C. produces a selection of different pulps.

NBSK is used in a variety of paper products including tissue grades, printing and writing papers, lightweight coated papers for catalogues, magazines and speciality papers. It is suitable for products requiring the highest tensile strength.

Photo courtesy of Forest Products Association of Canada

Unbleached NSK is a strong pulp, used for kraft and wrapping papers, specialty papers and linerboard. Special high purity unbleached kraft pulp can be used as electrical insulation.

Photo courtesy of Forest Products Association of Canada

To make BCTMP the pulping process applies heat, chemicals and a refining process on a non-chlorine environment. BCTMP in B.C. is suitable for manufacturing products such as coated containerboard, printing and writing paper and paper towel and napkins.

Photo courtesy of Forest Products Association of Canada

Dissolving pulps are bleached chemical pulp composed mainly of pure cellulose (90 per cent alpha-cellulose and over), that are used to manufacture various non-paper products. B.C.’s western hemlock species is particularly well-suited to making dissolving pulp. It can be used in the manufacturing of synthetic fibres such as rayon, plastic materials, lacquers and explosives.

Photo courtesy of Forest Products Association of Canada

Paper is increasingly used as a low-carbon recyclable material—a renewable alternative to fossil fuel-based packaging such as plastics and foams. Researchers in the BioProducts Institute at the University of British Columbia have stepped up to the challenge, designing what could be the very first N95 mask that can be sourced and made entirely in Canada. It’s also possibly the world’s first fully compostable and biodegradable medical mask. The prototype masks are made from B.C. wood fibres, including pine, spruce, cedar and even recycled paper.

Newsprint is an uncoated mechanical paper mainly used in the printing of newspapers. It is primarily made of mechanical pulp and can contain recycled fibre from old newspapers and magazines.

Photo courtesy of Forest Products Association of Canada

Uncoated papers, excluding newsprint, are composed of fibres mainly from mechanical pulping. They are used for inserts, flyers, magazines, catalogues, directories and books.

Photo courtesy of Forest Products Association of Canada

Lightweight coated papers can be gloss or matte finish and come in a variety of weights for printing magazines, catalogues, inserts, flyers, supplements and promotional materials.

Photo courtesy of Forest Products Association of Canada

Kraft papers are made predominantly from wood pulp. They are noted for their strength and, in unbleached grades, used primarily as wrappers and packaging materials. They can be converted into grocery bags, multi-wall sacks, tire wraps and butcher wraps.

Photo courtesy of Forest Products Association of Canada

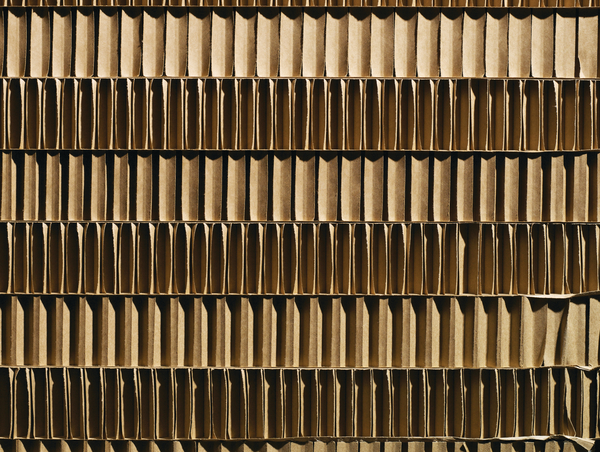

Component materials such as linerboard and corrugated medium are used in the manufacture of shipping containers, other corrugated board products, specialty liners and fibre boards.

Photo courtesy of Forest Products Association of Canada

Tissue grades, manufactured from kraft and recycled pulp, include bathroom and facial tissue, paper towels and napkins. They are manufactured for consumer, in-home and commercial use and away-from-home use, such as office and industrial buildings, schools and hotels.

With the province of British Columbia recognized as a global leader in sustainable forest management, you can specify B.C. forest products with confidence. Connect with suppliers of pulp an paper today.

Photo credit: Candace Kenyon

Subscribe for the latest wood projects, developments, tools and research.