MONAD: a four-storey mixed-use project in Kitsilano

In Vancouver’s Kitsilano neighbourhood, MONAD features three highly efficient condominiums built with wood-frame modular construction to maximize space and reduce disruption to the area.

- Prefabrication enabled the entire project to be craned into place over a weekend.

- Factory fabrication of the wood-frame modules took about three months.

- The architects chose wood because they wanted an adaptable material that could be precision cut, and offer flexibility within their system.

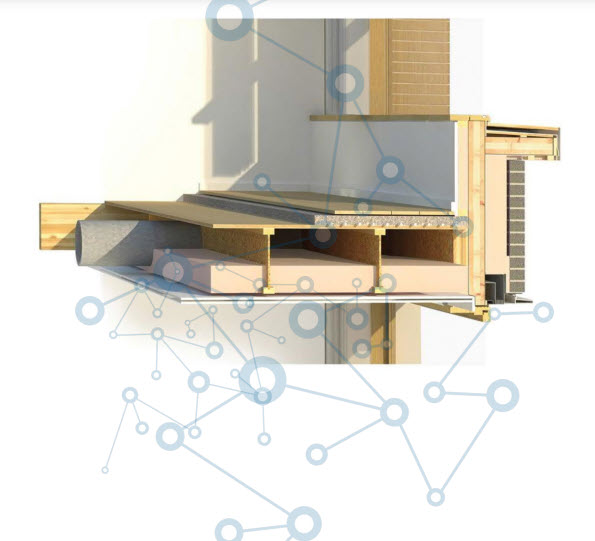

The innovative, systematized approach to infill development resulted in bright, airy dwellings that are more like “sky houses” than traditional condominium units. The MONAD system uses open-sided modules that, with the addition of bridging panels of different lengths, can be adapted to infill lots of varying widths. Low-carbon construction, a high-performance building envelope, and on-site renewable energy enhance the sustainability of the project. The four-storey mixed-use building includes a ground-floor commercial unit made from concrete construction. The top two units have access to a roof garden.

A high-quality system that offers flexibility

MONAD was designed to demonstrate an adaptable, scalable housing system which uses prefabricated wood components that can be modularized and used in a wide range of situations and building opportunities. The MONAD system allows owners to configure their interior space to suit their individual needs and offers the option of open-plan layouts.

Wood is a highly sustainable choice

The architects chose wood because they wanted an adaptable material that could be easily and accurately machined using advanced software. They also wanted a highly sustainable, carbon-neutral building system and they knew that wood is efficient in sequestering carbon. MONAD was built using a combination of laminated veneer lumber (LVL) and parallel strand lumber (PSL) for the beams and columns, along with I-joists for roof and floor joists. Dimension lumber was used for wall studs and non-structural partitions and plywood sheathing was used throughout.

A speedy schedule with little waste

Off-site prefabrication of the building modules helped to control costs, accelerated on-site assembly, and minimized noise and disruption to neighbours during construction. Off-site fabrication also reduced waste and allowed for improved quality control. Factory construction took about three months and new efficiencies with the system will allow future projects to be fabricated and built even more quickly. Installation took just two days, and the entire project was craned into placed and erected over a weekend.

“From the beginning, we said that the MONAD platform needed to be capable of constructing taller buildings, and it can. So, our original decision to use wood was based on our ability to prefabricate off-site and develop an even greater degree of automation with wood in that process.”

Oliver Lang, Principal and Creative Director of LWPAC