What is design for manufacture and assembly (DfMA)?

Design for manufacture and assembly (DfMA) is a design approach that focuses on both ease of manufacturing for the product parts and the simplified assembly of the final product. It combines two methodologies; design for manufacture and design for assembly. That is, from the initial stages of creation, decisions are based on avoiding problems during construction and improving efficiency.

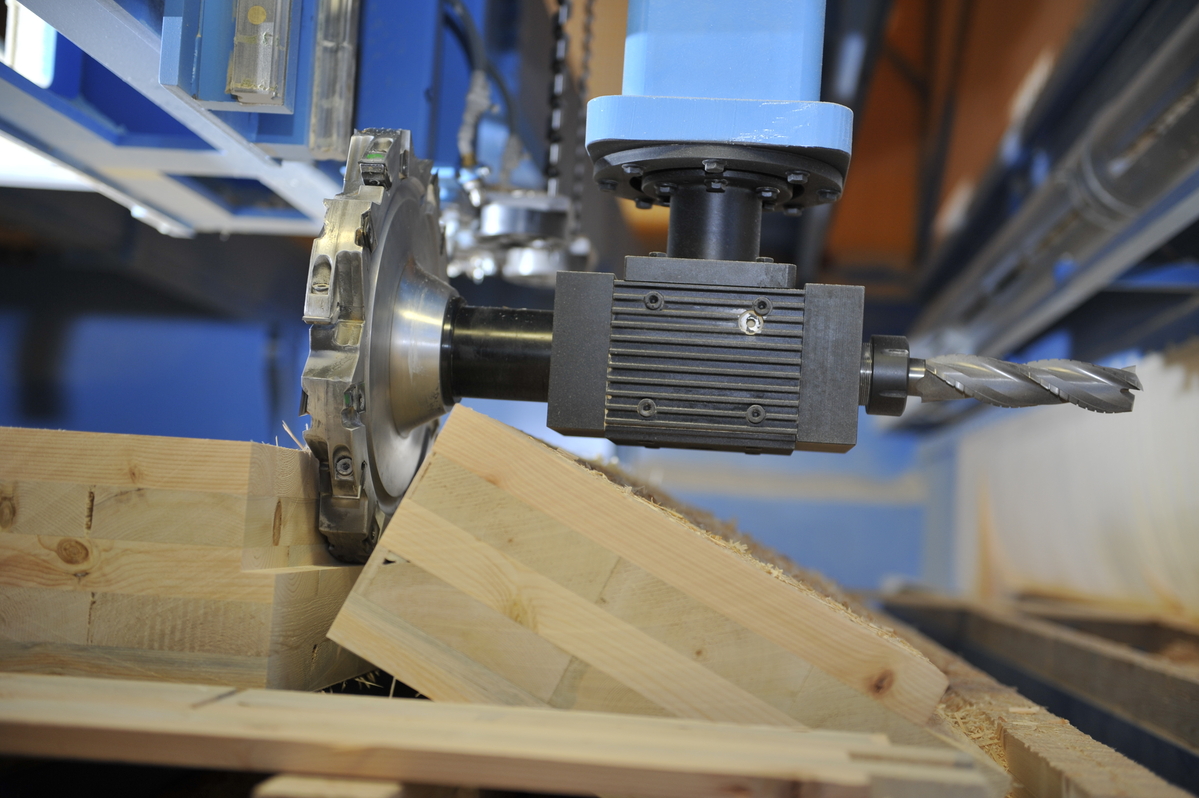

This is an approach used across many industries, and in construction, it is particularly well suited for mass timber using products like cross-laminated timber (CLT) or glue-laminated timber (glulam). This is because, when designing and building with mass timber, the construction itself is much more an assembly of parts, and is quite different from the design and construction of more traditional construction. Mass timber panels, beams and columns are manufactured offsite and transported to the construction site, prefabricated with all the stops and holes for accommodating the predefined installations, including MEP (mechanical, electrical, and plumbing). For the process to be smooth from beginning to end, it is essential to organize starting from the initial stages of the project, allowing diverse teams to connect early on to contribute to the final product, avoiding delays and setbacks at the construction site. It is at this point that building information modelling (BIM) helps a lot in the process.

Off-site prefabrication of CLT panels. | Photo credit: Swanky Photography