Showcasing resilient, sustainable and cost-effective multi-family housing solutions

Vienna House will be built to Passive House standards using prefabricated mass timber and light-frame-wood components.

- This seven-storey, multi-family building features mass timber-light-frame wood hybrid construction and includes cross-laminated timber (CLT) floors and light-wood frame prefabricated closed envelope panels.

- The first non-market multi-family housing project in B.C. to use building information modelling (BIM) from concept design through project delivery, and even for facility management.

- The project aims to help establish best practices for affordable and sustainable housing and is set to be a near-net-zero emission building.

A replicable mass timber model to help close the gap in affordable housing

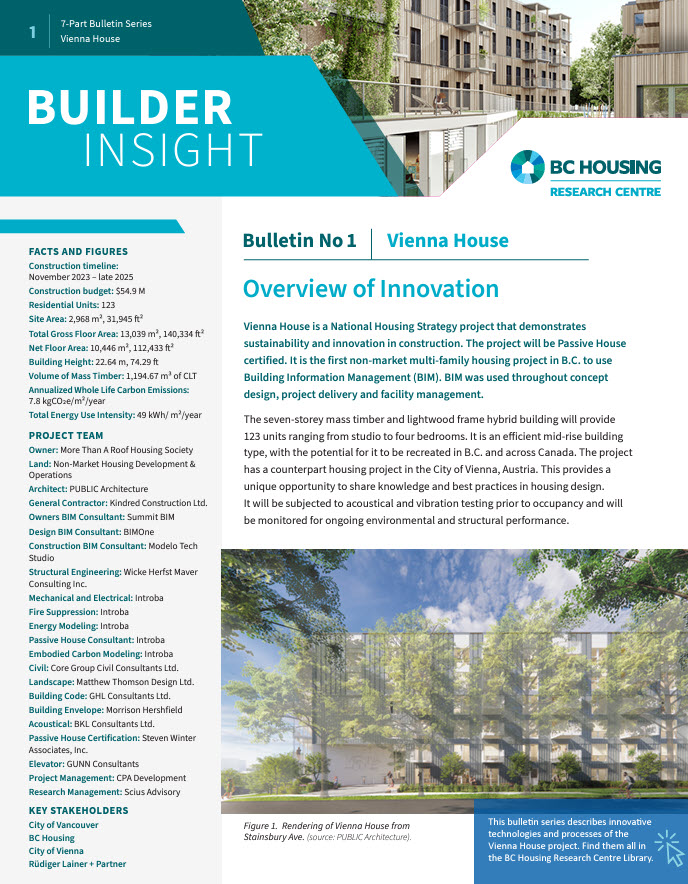

Vienna House explores and showcases mass timber as a solution to help alleviate the current shortage of affordable multi-family housing. This seven-storey, hybrid residential building will have 123 units ranging from studios to four bedrooms, accommodating a demographically diverse range of residents including low-income families, seniors and people with disabilities. It is designed as a mass timber and light-frame-wood hybrid structure, making it an efficient and replicable typology. The main structural building system includes cross-laminated timber (CLT) roof and floors, and light-wood-frame closed envelope panels.

A deep dive into whole building Life Cycle Assessment (wbLCA) and BIM-enabled mass timber and light-frame best practices

Vienna House will extensively use building information modelling (BIM) for prefabrication and construction efficiency, waste reduction, improved coordination and ease of hand-over for mid-rise affordable housing. It is B.C.’s first non-market, multi-family housing project to use BIM from concept design through project delivery. The project’s use of BIM has the goal of improving design and construction coordination to maximize the efficiency and accuracy of off-site fabrication of mass timber and wood frame assemblies.

Along with using BIM, a whole building Life Cycle Assessment (wbLCA) will be conducted to evaluate the embodied carbon benefits of the design.

As a demonstration project, the design team will share their learnings about mass timber hybrid prefabricated construction best practices, focusing on not-for-profit housing owners/operators, and the consultants and builders who work with them.

High-performance, affordable, resilient housing built to Passive House standards

Vienna House is designed to be affordable and sustainable. It will be Passive House certified and take advantage of mass timber’s thermal mass and natural insulating benefits.

The prefabricated panels will be manufactured offsite and delivered pre-insulated with low carbon bio-based insulation, pre-sheathed, pre-vapour barriered and pre-air barriered. With this approach, the building is expected to go up in only 12 weeks instead of the typical 20 weeks for an on-site build.

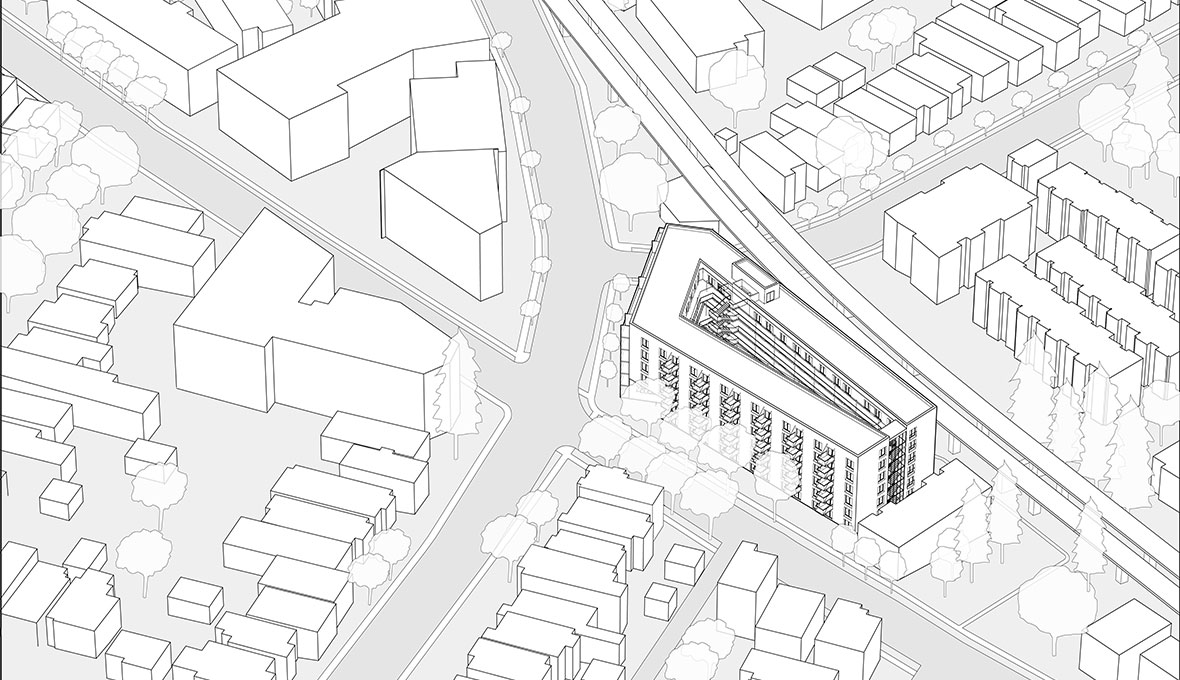

The project is a near-net-zero emission building designed to exceed the building code’s energy requirements by 25 percent—the equivalent of Step 5 in the BC Energy Step Code. With climate data estimates for 2050 in mind, the building strives to mitigate the impacts of hot weather for its occupants. To this end, the building is all-electric, with heating and cooling requirements that are facilitated by its Passive House design. Furthermore, a courtyard configuration provides natural cross-ventilation and exterior shading reducing solar heating in the warmer months. Heat pumps featuring CO2 air source technology minimize refrigerants and energy use. Additionally, studies are being conducted to assess the viability of rooftop solar photovoltaic (PV) electricity collection and battery storage, which would provide resilient power in the case of an emergency.

Other proposed sustainable features of the project include a Salmon-Safe certification for stormwater treatment and rainwater harvesting for irrigating plants and low-flow plumbing fixtures.

Along with being a Mass Timber Demonstration Program (MTDP) project, Vienna House is also one of ten projects supported by the Canadian Mortgage and Housing Corporation (CMHC) National Housing Strategy (NHS) Demonstration Initiative focused on innovative, affordable housing solutions.

The Mass Timber Demonstration Program (MTDP) provides funding for incremental costs in the design and construction of buildings that showcase emerging or new mass timber and mass timber hybrid building systems and construction processes. The program supports jobs and employment recovery in the design, engineering, construction, and product manufacturing sector. BC industry will benefit from lessons learned, results, and research findings that can help support future mass timber projects in the province. Learn more.