The future is wood

Why next-generation cities are turning to wood

Climate change and its associated effects may be a global challenge, but there is a role for local municipalities and districts to reduce their immediate impacts—whether it’s wildfires, flooding or finding low carbon construction alternatives. In response, cities and towns across British Columbia are turning to light-frame wood and mass timber design and construction.

Wood construction is a central component of the Union of BC Municipalities (UBCM) housing strategy for British Columbians. Thirteen B.C. communities have signed on as early adopters of mass timber for taller wood building. At the provincial level, mass timber is being encouraged as part of its capital construction programs, particularly in the development of healthcare facilities and the expansion or replacement of public facilities such as the Royal BC Museum.

Just this past summer, the City of Vancouver made amendments to allow mass timber construction up to 12 storeys for residential and commercial uses, doubling the current height allowance for wood from 6 storeys. As the City points out, this will make it easier to build with low carbon materials, support housing affordability, and remove barriers for the construction industry at a time of crisis and economic recovery. Surrey, the province’s fastest-growing city, continues to make timber central to its infrastructure expansion and urban design. Along with more than 50 other municipalities, it was an early adopter of the Province’s Wood First Initiative that recognizes wood’s social, environmental and economic benefits and makes it the material of choice for public buildings.

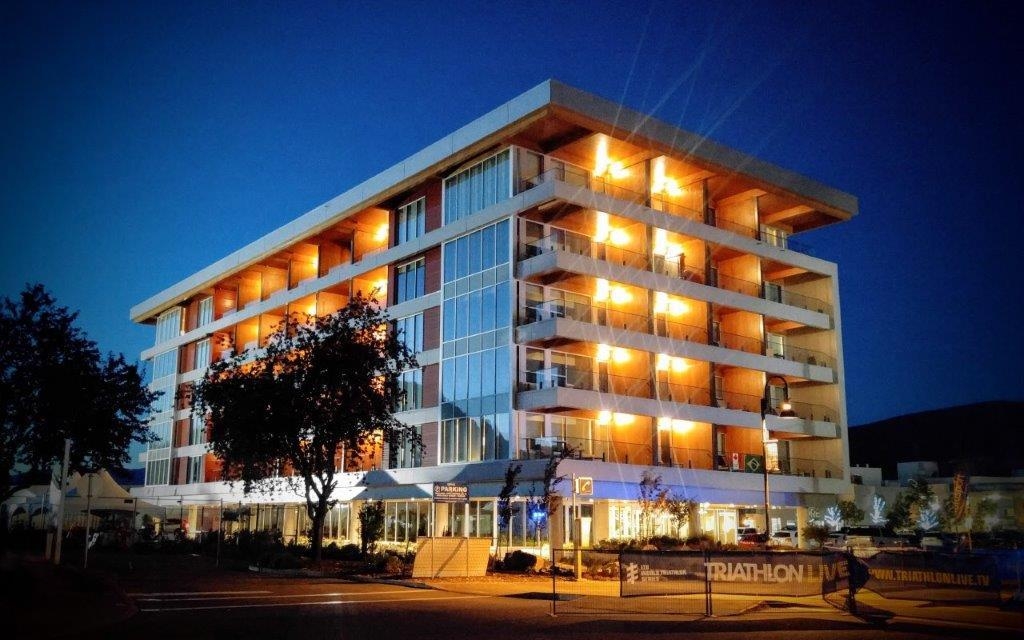

Top left: Brock Commons Tallwood House, Photo credit: KK Law | Top right: The Heights, Photo Credit: Raffi Karakouzian, courtesy of Cornerstone Architecture | Bottom: Rendering of Clayton Community Centre, Photo courtesy of hcma