Western larch is produced predominantly as part of the Douglas-fir-larch species mix. Its properties are similar to Douglas-fir so the species are sometimes sold mixed. Western larch is attractive, and some high-grade material is used for interior finish products.

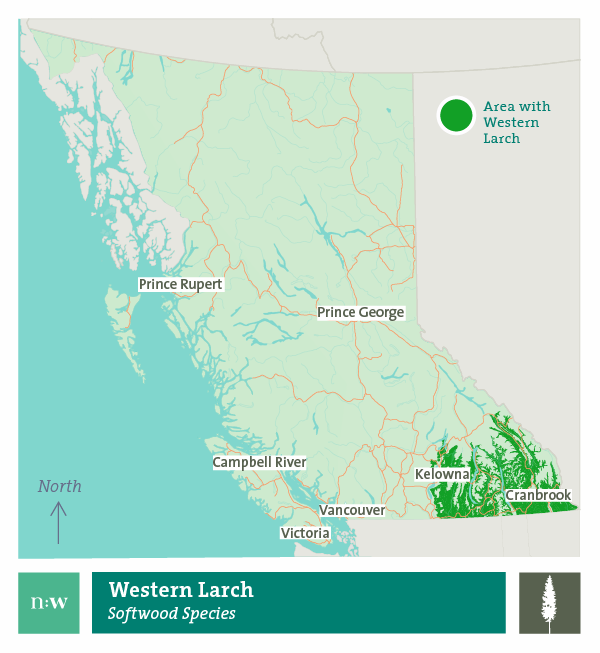

Western larch grows in valleys and on the lower slopes of mountains in B.C.’s southern interior. It produces hard, strong wood that is used to produce heavy timber for products such as planks and boards, poles, railroad crossties and mine timbers.