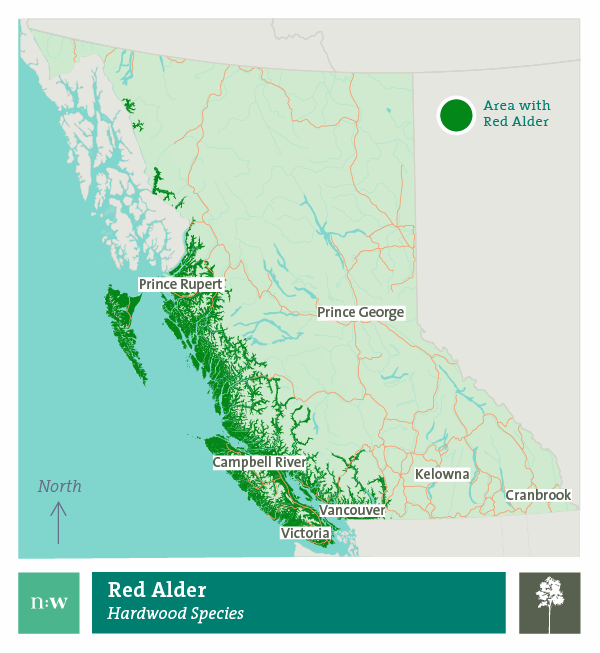

Red alder is the most plentiful hardwood on British Columbia’s (B.C.’s) coast. The medium-sized broadleaf tree grows up to 24 metres and has a life span of 40 to 60 years. Its wood is moderately dense and uniformed textured, and it is an important species for many specialty products.

Red alder is used in furniture, flooring, cabinets, turnery, decorative veneer and other home décor products. It is also used for high-value products such as doors and shutters, domestic woodenware and toys.