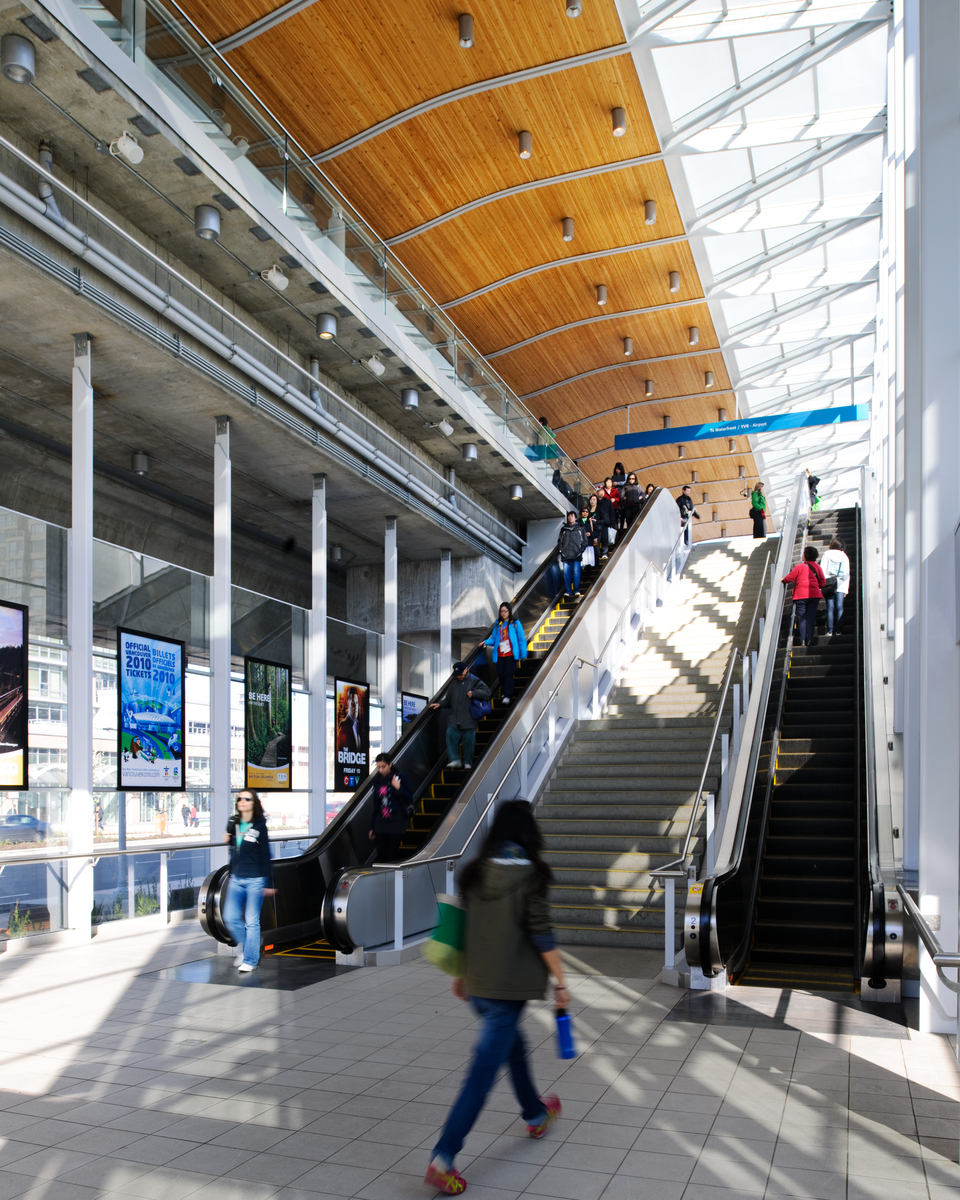

Dramatic use of wood for mass transit

The Richmond-Brighouse station is one of four on the rapid transit Canada Line that share strikingly similar design features. The line runs from Vancouver to Richmond and was built in time for the opening of the Vancouver 2010 Olympic and Paralympic Winter Games. The four stations are thematically connected by the judicious but dramatic use of wood, which was one of the key objectives for the elevated mass transit design.

- Wood used in the prefabricated panelized roofs expedited construction.

- Hybrid wood construction combined state-of-the-art technology with abundantly available dimensional lumber.

- Designers built upon the ‘kit of parts’ approach of Expo Line stations and the customized approach used for Millennium Line stations.

Signature wood roof a unifying theme for the rapid transit stations

The Richmond-Brighouse station is one of the southernmost stations on the Canada Line and it’s situated at the heart of Richmond, within walking distance to shopping, community centres and other important amenities. Designers used expansive exposed wood as the central feature of this and the other three urban rapid transit stations along the Canada Line system that connects Vancouver with Richmond.

The Richmond-Brighouse station was designed as part of a group of stations that would be similar in design and offer an attractive and welcoming environment while being cost efficient. The distinctive wood canopy provides protection from the Lower Mainland’s inclement weather along the length of the platform and establishes a clear identity for the southern portion of the Canada Line.

Prefabricated panelized wood roof sped up construction

The use of prefabricated panelized roof panels constructed from Douglas-fir dimensional lumber solidly packed together on edge rapidly expedited installation. The panels were prefabricated off-site to ensure the highest quality of the finished product and to facilitate rapid installation. Each panel was lifted into place by crane, requiring only a week and a half to install the entire roof.

The prefabricated panelized roofing system is replicable and adaptable to a wide variety of scales and applications. It offers quality control and reduced construction time and requires only modest investment in manufacturing infrastructure.

“When you bring wood into a station it adds a certain touch, which can be very nice. So there is hardly a station we work on now that doesn’t have some measure of wood in it.”

Paul Fast, structural engineer