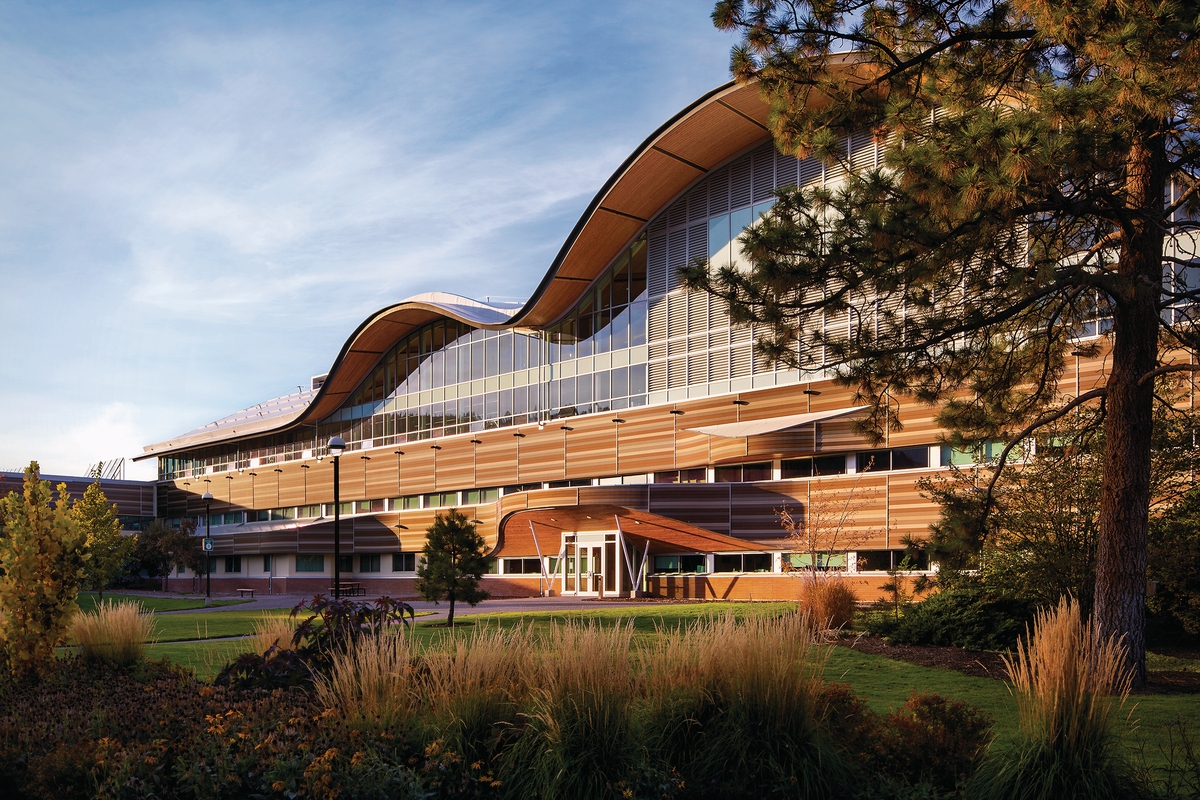

The eye-catching undulating timber roof of the two-storey addition built on top of the Thompson Rivers University’s “Old Main” building echoes the surrounding landscape.

- Not only visually striking, the roof provides ample open-air space for the functional elements inside.

- The roof, which covers an area equivalent to a football field, was completed in seven weeks.

- The interior features many wood finishes, including millwork, panelling and acoustic treatments.

Located amid rolling grasslands above the confluence of the North and South Thompson Rivers in the south-central region of the province, this addition houses the university’s law school.

To meet a tight summer schedule, the panelized roof structure was prefabricated off-site from glue-laminated timber (glulam) beams, wood joists and plywood sheathing. It was installed in only seven weeks, with the panels locking into place like puzzle pieces. Exterior soffits are finished in a smooth western red cedar cladding, making the sweeping serpentine roof appear like a floating ribbon of wood above the south-facing glass curtain wall.

Lightweight champion: wood eases burden on existing structure

Its lighter wood hybrid design has the added benefit of minimizing the additional load on the original 1960s structure, transforming an otherwise forgettable low-rise building into a campus focal point.

A south wing comprises teaching spaces and lecture halls, while the north wing houses the law library and faculty offices. Expansive interior glazing of the double-height atrium creates transparency and sightlines between the lobby and the library reading room. A sculptural spiral staircase complements the design—its top-floor landing accommodates a wraparound study counter with mountain views, and doubles as a panoramic venue for informal gatherings.

An altogether modern, flexible design that can shift with programming and student population changes, this is a law school ready for the future.