Speed of construction, reduced building weight, and the cachet of a timber design convinced the owners of Penticton Lakeside Resort to use wood instead of concrete when expanding their waterfront resort.

- Six-storey structure completed in just under one year, a target impossible without using cross-laminated-timber (CLT).

- Use of exposed glue-laminated timber (glulam) and CLT in both rooms and public spaces give the hotel a contemporary look, while also saving money by eliminating the need to add interior finishes.

- Locally-produced CLT panels were used for all major shear elements of the building, including floor and roof structures, balcony separation walls, and the vertical walls which separate the exterior decks.

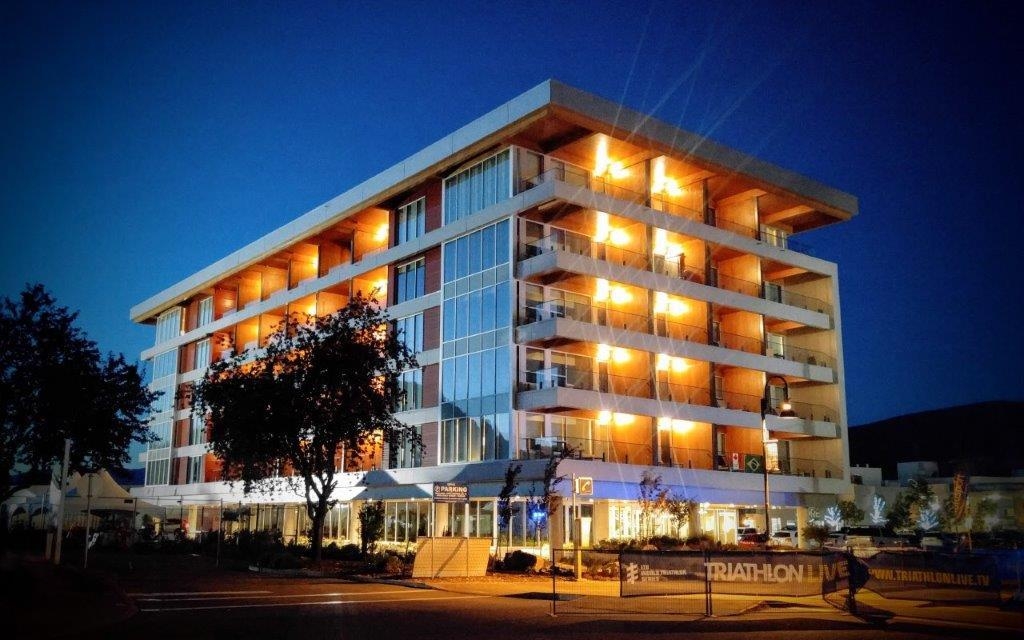

Situated on the south end of Okanagan Lake, an area popular with tourists and locals alike for its recreational activities, wineries, and fruit orchards; this six-storey, 70-unit hotel sets a new standard for the use of mass timber in commercial and hospitality projects.

The compromised soil conditions of the floodplain site meant that the reduced weight of mass timber compared to concrete lowered the construction costs significantly. Each floor consists of 70 locally produced cross-laminated timber (CLT) panels, making this the largest mass-timber project in the region.

A unique and modern addition to Penticton’s waterfront

The exposed timber structure—made of a Douglas-fir glue-laminated timber (glulam) post-and-beam frame with CLT floors, roof, shear walls, stairwells, and stairs—envelops visitors with a sense of warmth and modern rusticity. Glulam was also used to build a dramatic nine-metre-high wall using a double lattice of beams to frame the windows.

The floor panels were loaded on the truck at the factory not far from the site and lifted by crane and lowered into place in a single movement. Each floor took an average of one week to install and the entire building was completed in just under a year, in time for the resort’s busy summer season.

There’s a lot of money left on the table if you miss a summer at a resort like this. When you compress a construction schedule by using prefabricated wood panel products, it results in real, intended financial benefits.

David Prystay, General Manager, RPB Hotels & Resorts