The Longhouse at The University of British Columbia is a striking example of Coast Salish architecture, a single-storey heavy timber structure that is a visual tribute to regional western red cedar, inside and out.

- Coast Salish people have historically used cedar for everything from furniture, textiles, basket weaving, to larger, structural applications such as longhouses.

- The four striking cedar houseposts are hand-carved and a metre in diameter.

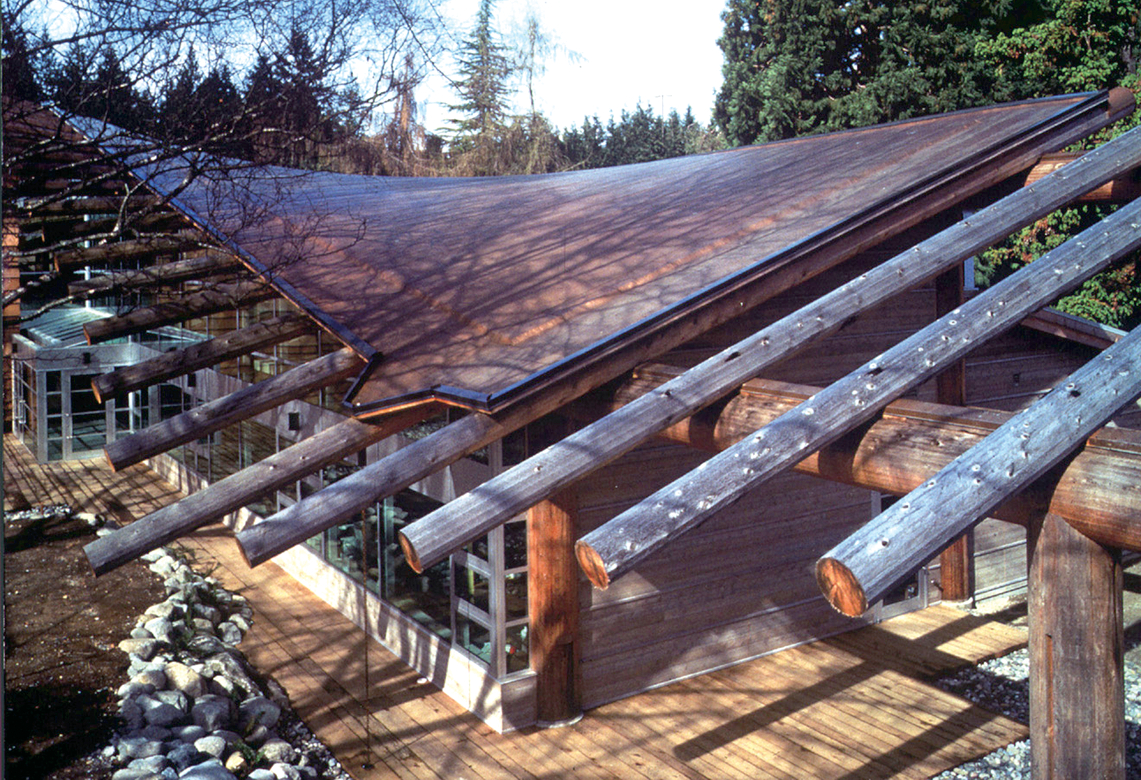

- The wood roof structure is designed to resemble the wing of a bird in flight.

The building serves as a home–away-from–home to the Indigenous, Métis and Inuit students, faculty, and staff on campus. Students have access to a study space, a computer lab, and gathering spaces. The Longhouse is also the location for administrative offices, including those of the First Nations House of Learning. The First Nations Longhouse reflects Indigenous Peoples’ long history and cultural practice of using wood in community buildings where artists and ceremonies keep traditions alive. The design combines traditional wood construction techniques of the Coast Salish peoples with contemporary architectural forms.

A parabolic curved roof

The roof of the Longhouse is a dramatic curve, resembling the wing of a bird in flight. The structure is constructed of oversized western red cedar logs, covered in copper. Cedar was chosen for its ability to accommodate the complex shape, and because it is a traditional material of value to the coastal First Nations people.

Locally sourced red cedar is the star

The Longhouse is a Musqueam-style shed: a single-storey, heavy timber structure sited to align with the cardinal compass directions. As the focal point of the Longhouse, the great hall—Sty-Wet-Tan—is a 334 square-metre gathering space that showcases traditional wood building techniques and decoration. The four houseposts and supporting roof beams in the hall are western red cedar, hand-carved in traditional Indigenous designs by local artists. The houseposts are a metre in diameter. The structural framing, as well as most of the interior finishes and exterior cladding of the Longhouse are made of local western red cedar.

Traditional look meets modern technique

The timber members were milled to a constant diameter and the detailing for the steel connections cut at the processing factory, and then assembled onsite. Light wood-framed shear walls constructed of hem-fir studs and sheathed in Douglas-fir plywood provide lateral bracing. The exterior cladding is rough-hewn shiplap planks, naturally weathered to a soft grey. The interior is mostly tongue-and-groove planks with exposed rafters and purlins, or horizontal beams, all naturally stained.