Design for Deconstruction

Thinking about the building's end-of-life

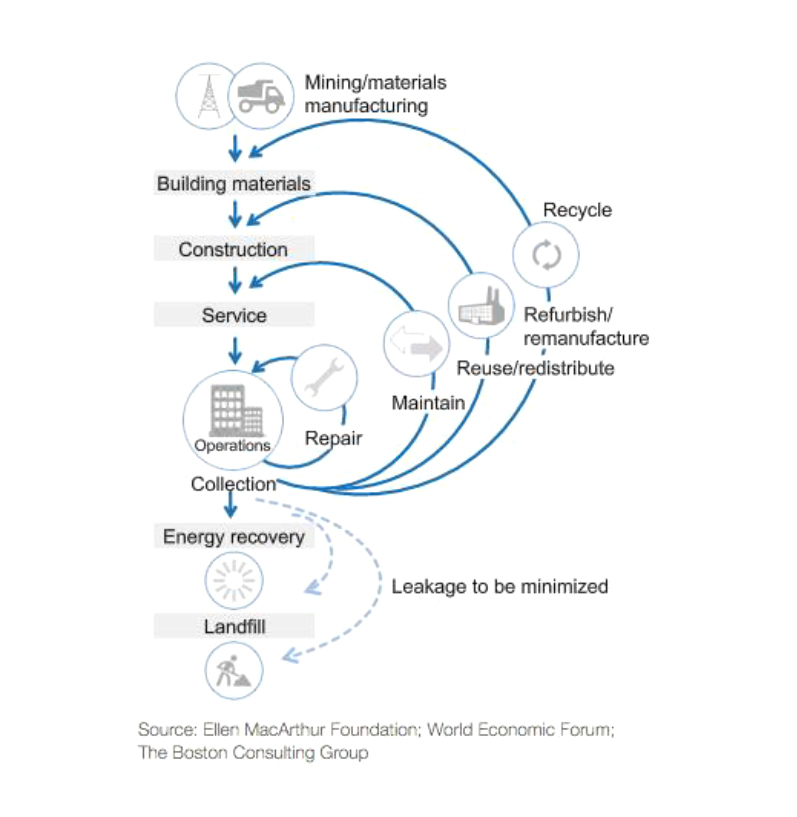

The so-called design for deconstruction (known by the acronym DfD, or design for disassembly) considers how all decisions made in the design phase can increase the chances of reusing the building parts at the end of their useful life. As defined in the EPA (United States Environmental Protection Agency) manual, “the ultimate goal of the design for deconstruction (DfD) movement is to responsibly manage end-of-life building materials to minimize the consumption of raw materials. By capturing materials removed during the renovation or demolition of buildings and finding ways to reuse them in another building project or recycle them into a new product, the overall environmental impact of end-of-life building materials can be reduced. Architects and engineers can contribute to this movement by designing buildings that facilitate adaptation and renovation. Designing for deconstruction is designing so that these resources can be economically recovered and reused.” Taking the example of Canada, buildings are the largest consumers of raw materials and energy and the biggest contributors to the waste stream by weight, which equates to 3.4 million tons of building materials sent to landfills annually, representing an estimated 1.8 million tons of incorporated carbon.

Photo credit: KK Law