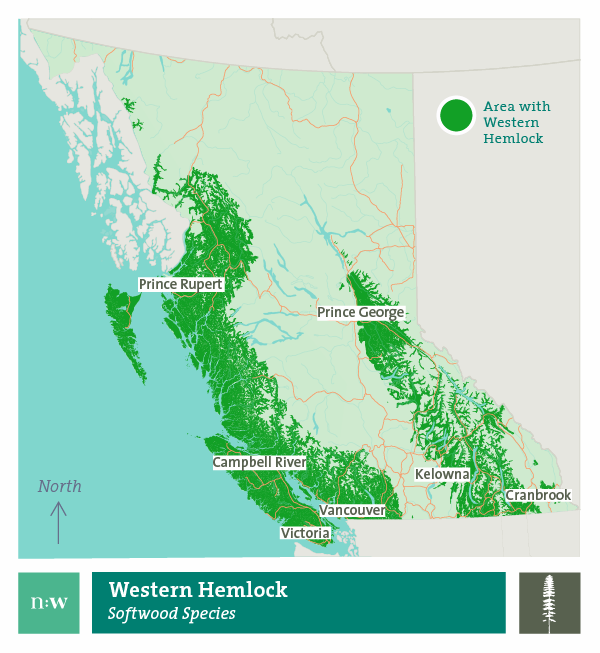

Western hemlock grows along B.C.’s coast on both the east and west sides of the Coast Range as well as in the interior wet belt west of the Rocky Mountains. It is a large tree that typically grows 30 to 50 metres and has conspicuously drooping new growth at its top. Western hemlock is used for general construction, roof decking and plywood, as well as for laminating stock and the production of glue-laminated and solid beams. Its strength and stiffness make it a preferred material for use in horizontal components and longer spans.

Western hemlock is the most plentiful tree species on the coast of B.C. It is commonly sold and shipped with amabilis fir under the name hem-fir, which has an extremely wide range of uses because it offers good strength, appearance and working qualities.